In the exhilarating journey from idea to a tangible product, prototyping plays an essential and transformative role. Every industry giant and startup alike understand that the magic of innovation is not just found in the end product but in the meticulous process of refining it. This is where product prototyping ascends as a critical tool for industrial design and user experience design.

It is the art of creating preliminary models of products, which allows teams to explore ideas, iterate design solutions, and deliver unparalleled user experiences. Here, we’ll dissect why prototyping is a non-negotiable step in product design, present methods for prototyping hardware, and share inspirational examples of successful products born through this process.

Why Prototyping Reigns Supreme in Product Design

To appreciate the value of prototyping, one must recognize the complexities involved in creating products that resonate with consumers. It’s not merely about aesthetics; it’s the marriage of form, function, and feel. Prototyping empowers designers to breathe life into abstract concepts and scrutinize their ideas under the harsh light of real-world application.

It’s easy to get caught up in the excitement of a new concept and overlook flaws or challenges that may arise once a product is in the hands of users. Prototyping allows designers to identify these issues early on, saving time, resources, and ensuring a smoother user experience.

Additionally, prototyping facilitates collaboration between different teams involved in the product design process. By having a tangible representation of a product, designers can easily communicate their vision to engineers, marketers, and other stakeholders. This alignment of ideas leads to more efficient decision-making and ultimately results in a stronger end product.

The Benefits of Prototyping in Product Design

Improved user experience

By involving users in the prototyping process, designers can gather valuable feedback and insights to improve the overall user experience of the product.

Cost-effective

Prototyping allows for design flaws to be caught and corrected early on, saving time and money in the long run.

Faster development

With prototyping, designers can quickly iterate and test different ideas, resulting in a faster development process.

Clear communication

Prototypes provide a tangible representation of the product, making it easier for designers to communicate their ideas and for stakeholders to provide feedback.

Minimizes risk

By testing and refining prototypes, designers can identify potential issues and risks before the product is mass produced, reducing the chances of failure.

Better decision-making

With a prototype in hand, designers can make informed decisions on how to improve the design rather than relying on assumptions or guesswork.

Competitive advantage: By using prototyping as a part of the design process, companies can stay ahead of their competition by continuously improving and refining their products based on user feedback.

Types of Prototypes

There are several types of prototypes, each serving a different purpose in the product development process. Some common types include:

High-fidelity prototypes

These are more advanced prototypes that closely resemble the final product in terms of look, feel, and functionality. They may be made with 3D printing, virtual reality, or computer-aided design tools.

Low-fidelity prototypes

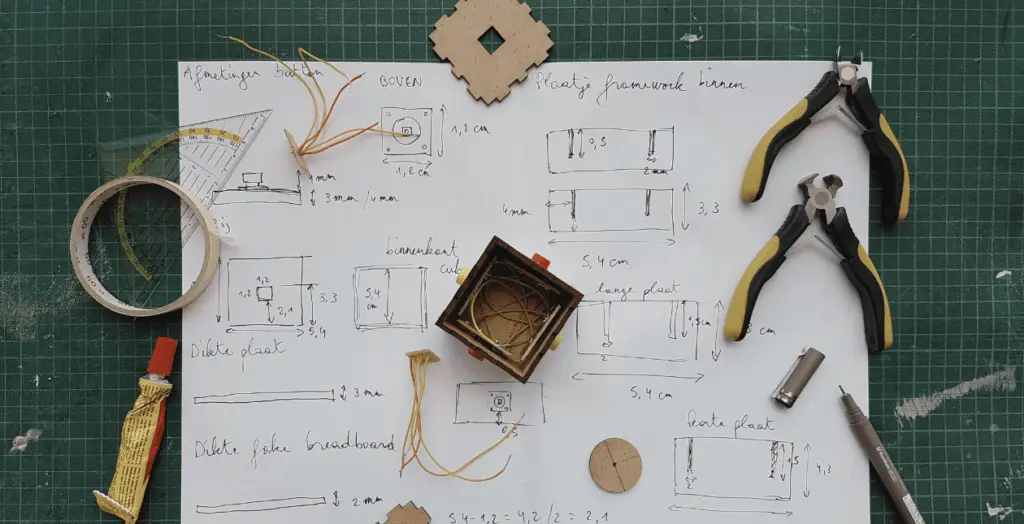

These are quick and simple prototypes that give a rough idea of the product’s functionality and design. They are usually made with low-cost materials like paper, cardboard, or foam.

Interactive prototypes

These prototypes allow users to interact with the product in a realistic way, providing more accurate feedback and insights for designers.

Functional prototypes

Similar to interactive prototypes, functional prototypes are fully functioning versions of the product that can be tested and refined before mass production.

Digital prototypes

With the rise of technology, digital prototyping has become increasingly popular. These prototypes use software and computer simulations to test and refine designs before moving on to physical production.

Paper prototypes

As mentioned earlier, paper prototypes are a type of low-fidelity prototype that allows for quick ideation and iteration. They can be easily modified and shared with stakeholders for feedback.

Virtual prototypes

These are digital representations of the product that can be viewed and manipulated in a virtual environment. This allows for testing and refining without the need for physical materials.

Methods for Hardware Prototyping

When it comes to translating ideas into physical reality, hardware prototyping stands out. It involves a spectrum of techniques, each with unique advantages, that convert digital designs into hands-on, tangible experiences.

3D Printing

This cornerstone of modern industrial design enables the rapid creation of complex geometries impossible to achieve with conventional manufacturing methods. From iteration speed to cost-effectiveness, 3D printing is a boon for designers seeking flexibility and precision.

CNC Machining

For prototypes that need to withstand rigorous testing or showcase functionality, CNC machining offers the production of parts with industrial-grade materials. It’s a go-to for testing the durability and fit of components, ensuring that the final product will hold up to user expectations.

Injection Molding

Although commonly associated with mass production, injection molding can be an excellent prototyping method for high-fidelity models. It provides a glimpse into how a product will feel and perform when manufactured at scale and allows testing with the actual materials and finishes intended for the final product.

Laser Cutting and Engraving

Ideal for creating precise and customized components, laser cutting and engraving add a layer of detail to prototyping that can elevate the user experience. These methods allow designers to add texture, grip, and aesthetic flourishes that can make a product stand out in a crowded market.

Investing in one or a combination of these methods is crucial for companies planning to produce a new product. It’s not enough to have a concept; you need a working replica to test, touch, and tinker with.

The power of prototyping in Product Development

Prototyping is the crucible in which good products are forged into exceptional ones. For any company looking to produce a new product, embracing prototyping is an investment in future success.

Industries evolve, technologies advance, but the principle of listening to the user remains the cornerstone of product development. Product prototyping is not just about discovery; it’s about placing the user at the heart of every decision.

Remember, behind every groundbreaking product lies a story of iteration, feedback, and refinement—a story that begins with a prototype. Whether you are a seasoned industrial giant or a budding entrepreneur, never underestimate the transformative power of prototyping on the journey from concept to user experience masterpiece.